NECK FITTING

This page looks at the process of attaching the neck to the body - and to some degree rehashes some of the material on other pages.

I use a traditional dovetail joint to attach my necks to the body. (Technically it is a tapered dovetail). I use this technique (as opposed to bolt on necks, for example) for a variety of reasons. Partially I am a bit of a traditionalist, and this is the traditional method. I am used to it - I have been doing it for 30 years and am quite familiar with it, and pretty good at it. When I started no one was using bolt on necks and there was no hardware to make it an easy choice.

I do not believe that a dovetail is "better" than other methods - it is just the way I do it. There seems to be a lot of controversy these days over which method is "better" - and I think this is silly. Either method (and there are others as well) is just fine if executed well.

This

is the jig I use to cut the dovetail in my bodies. I cut the dovetail

after the end blocks are attached to the ribs but before the top or back

is attached. I use a router with a dovetail cutter and a template

follower to follow the edge of the jig. The jig is adjustable for

size, and matches the shape of the jig for the neck dovetail.

This

is the jig I use to cut the dovetail in my bodies. I cut the dovetail

after the end blocks are attached to the ribs but before the top or back

is attached. I use a router with a dovetail cutter and a template

follower to follow the edge of the jig. The jig is adjustable for

size, and matches the shape of the jig for the neck dovetail.

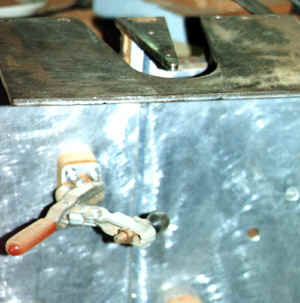

This

is the jig for cutting the dovetail on neck blanks. Although the

photo doesn't show it well, there is an alignment piece that fits in the

truss rod slot, and the De-Sta-Co clamps hold the neck in place.

The dovetail is cut with the same dovetail cutter/template follower as

is used for the body.

This

is the jig for cutting the dovetail on neck blanks. Although the

photo doesn't show it well, there is an alignment piece that fits in the

truss rod slot, and the De-Sta-Co clamps hold the neck in place.

The dovetail is cut with the same dovetail cutter/template follower as

is used for the body.

Here

I am fitting the neck dovetail to the body. There are several adjustments

to make (depending on how accurately my jigs (above) worked. The neck

(fingerboard) must be centered on the centerline of the body. In

addition the neck is slightly angled back from the plane of the top so

that the bridge will be the correct height. (More about both of these

later) Most of the adjustments are made to the sides of the

neck (the cheeks) which rest on the sides of the guitar. This is where

the angle of the neck to the body is corrected -- both side to side and

the angle back from the plane of the top. After these adjustments

are made, I correct the dovetail itself so that it fits tightly in the

cavity in the body.

Here

I am fitting the neck dovetail to the body. There are several adjustments

to make (depending on how accurately my jigs (above) worked. The neck

(fingerboard) must be centered on the centerline of the body. In

addition the neck is slightly angled back from the plane of the top so

that the bridge will be the correct height. (More about both of these

later) Most of the adjustments are made to the sides of the

neck (the cheeks) which rest on the sides of the guitar. This is where

the angle of the neck to the body is corrected -- both side to side and

the angle back from the plane of the top. After these adjustments

are made, I correct the dovetail itself so that it fits tightly in the

cavity in the body.

The

last step in fitting the neck is to carefully perfect the joint between

the body and the neck. To get a perfect fit I place a small sheet

of sandpaper between the body and the neck, hold the neck in tightly and

slowly withdraw the sandpaper. The result, with only a few strokes,

is a perfect fit.

The

last step in fitting the neck is to carefully perfect the joint between

the body and the neck. To get a perfect fit I place a small sheet

of sandpaper between the body and the neck, hold the neck in tightly and

slowly withdraw the sandpaper. The result, with only a few strokes,

is a perfect fit.

Another photo

of the same step. These days I do most of this "slip

fitting" before the neck is finished, and before all of the lacquer

is on the body. This is because the slip fitting sometimes leaves

small scratches in the finish, and this makes it easy to eliminate them.

Another photo

of the same step. These days I do most of this "slip

fitting" before the neck is finished, and before all of the lacquer

is on the body. This is because the slip fitting sometimes leaves

small scratches in the finish, and this makes it easy to eliminate them.

Gluing in the neck. the big C clamp I have used on virtually every

guitar I have made.

Gluing in the neck. the big C clamp I have used on virtually every

guitar I have made.

This website and all of its content, text and images are copyright ©1997-2011 by Charles A. Hoffman. All rights reserved.